HFR Software Change History

The current Software Revisions and upgrade token part numbers are listed below. The Version History of HFR software, Flow Meter software and Tank Stand software is also listed below. The HFR software, Flow Meter software and Tank Stand software can be found by navigating to Advanced Setup Screen 5 on the ADM.

To upgrade to a newer software version, order the appropriate “Software Upgrade Token” as listed below. To upgrade the software in a particular module, install the upgrade token into the module programming socket, cycle power, then allow the corresponding module to update its corresponding software image. The red LED on the corresponding module will stop blinking when the module software image is updated. It may take a few minutes, especially for the ADM module to complete the update process. The update process may need to be repeated for each module, until the software versions outlined in the revision numbers below match between the software version indicated and the Advanced Screen #5. For additional instructions, refer to the maintenance section of the HFR instruction manual (313997) for instructions on how to upgrade the modules.

For PLC and CGM related Fieldbus and other important integration files Click Here

See instruction manual 313997 for complete details on the Graco HFR Metering System.

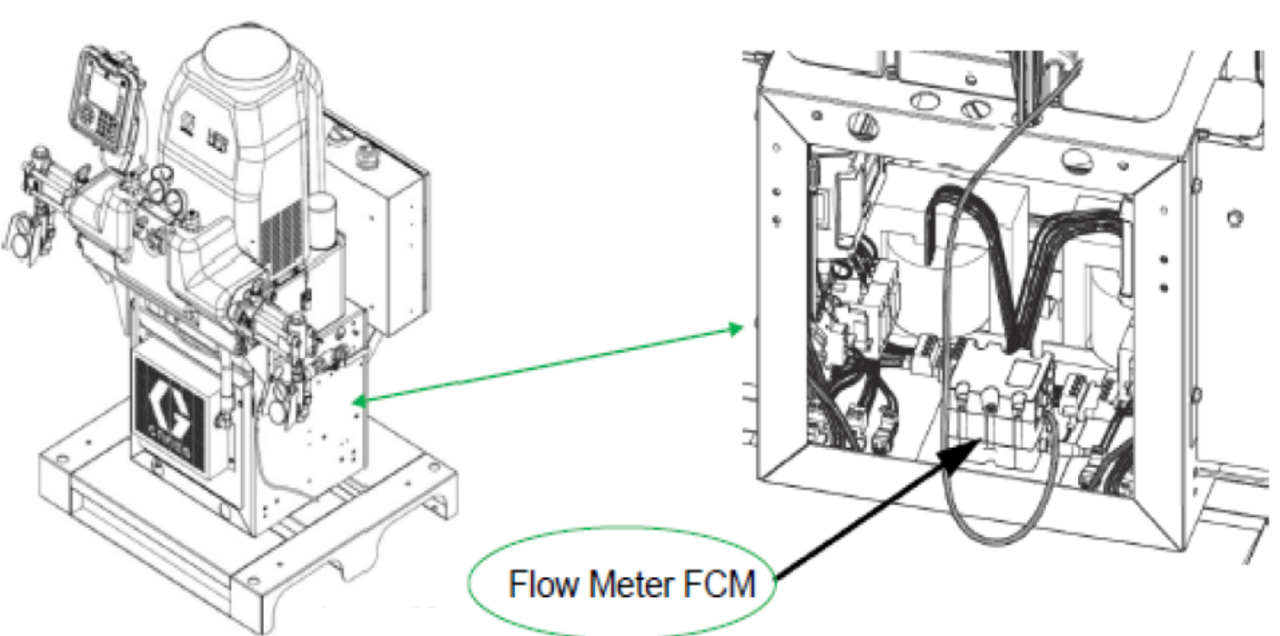

See instruction manual 3A1657 for complete details on the Graco HFR Flow Meter Kits.

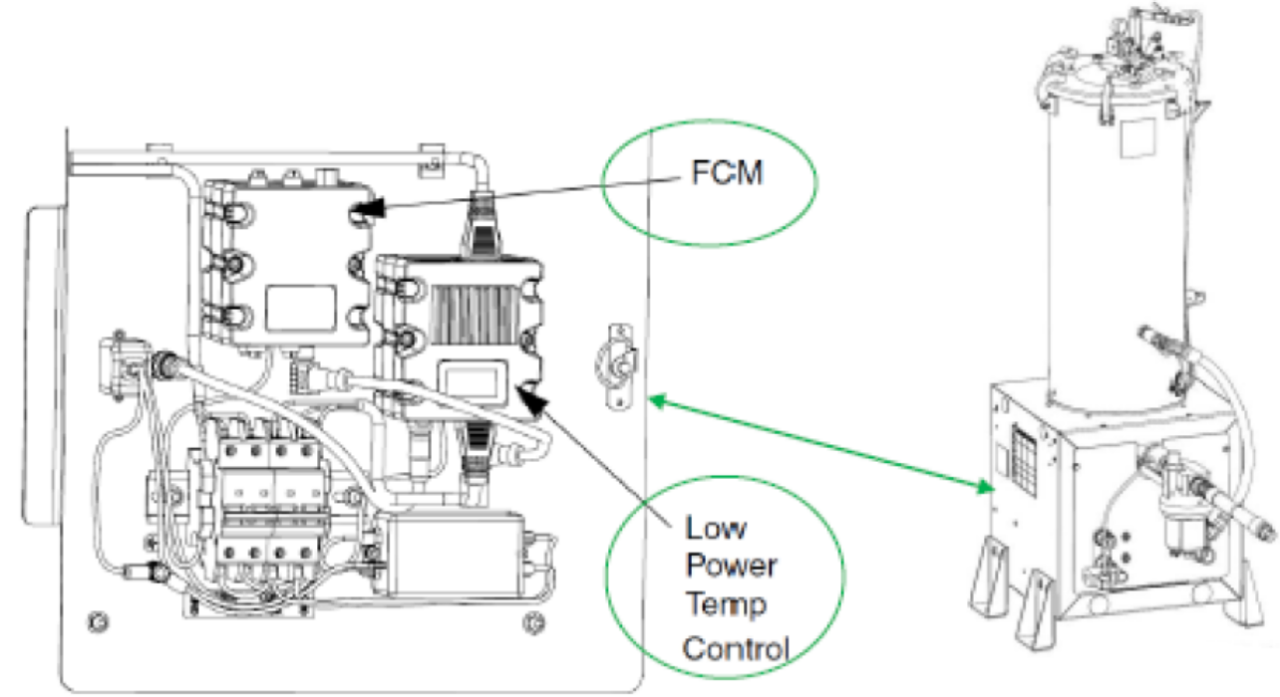

See instruction manual 3A1299 or 3A0395 for complete details on the Graco Tank Stands.

Software Upgrade Token 16H822 Series ZBU

- System 16H822zbu.gti (Software Link) version 1.13.028

- Advanced Display (ADM): 16E122 version 1.18.080

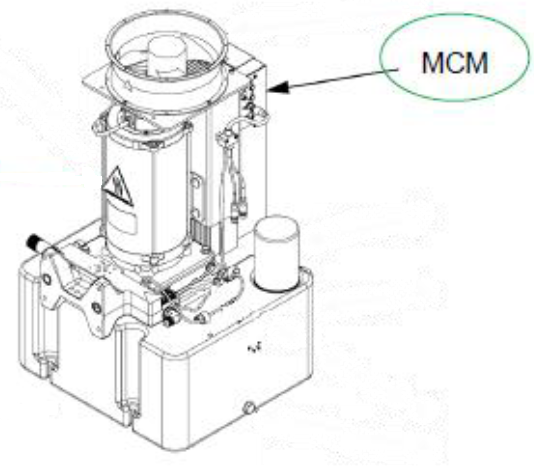

- Motor Control Module (MCM): 15Y820 version 1.13.065

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.004

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.015

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

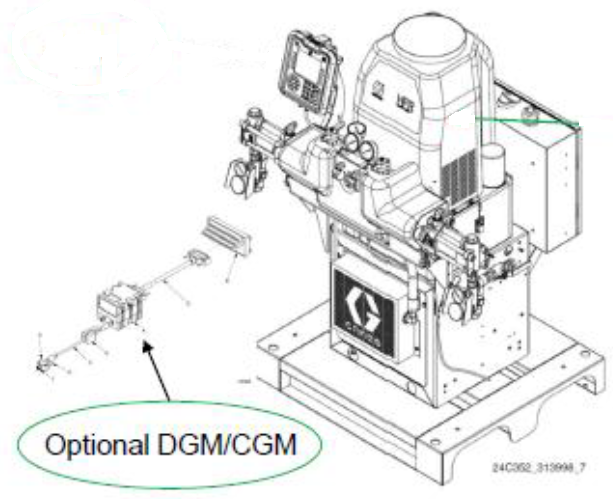

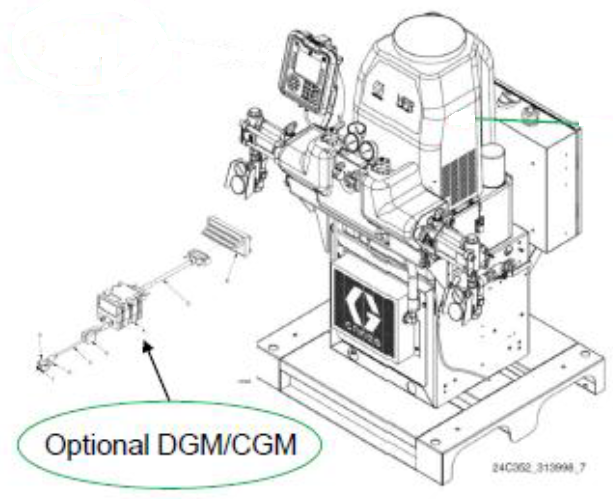

- Discrete Gateway Module (DGM): 16D773 version 1.05.008

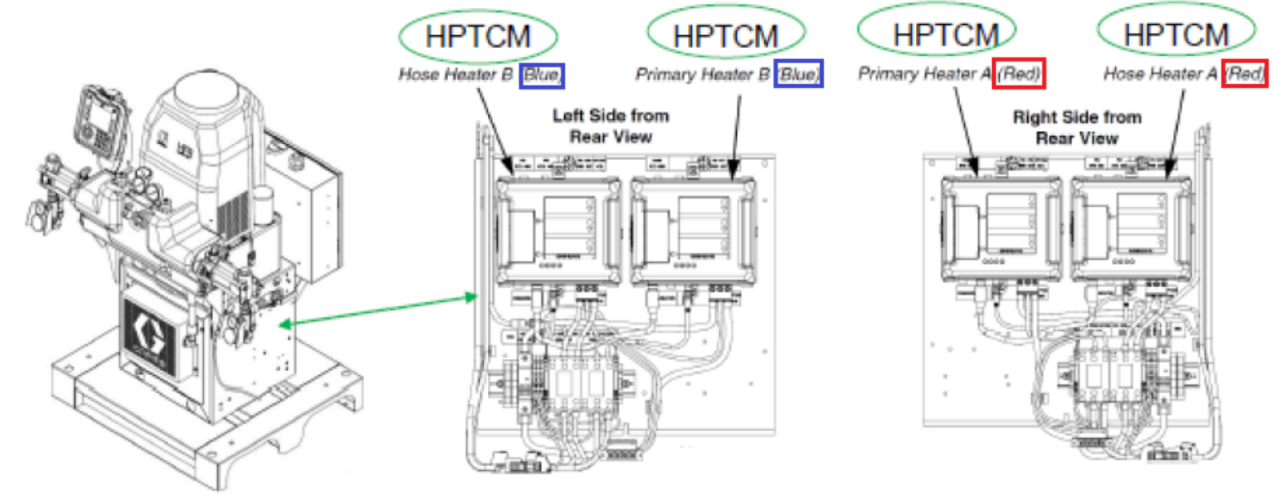

- Temperature Control Module (TCM): 15M871 version 1.08.002

- Mix Head Power Pack (FCM3): 16A039 version 1.10.003

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

- Added Customer Chart Record Feature, which can be turned On or Off via the fieldbus.

- Fixed a bug where the Auto Pressurize feature was not working when the recirculation valves were closed via the fieldbus interface.

Software Upgrade Token 16H821 Series ZBT

- System 16H822zbt.gti (Software Link) version 1.13.025

- Advanced Display (ADM): 16E122 version 1.18.075

- Motor Control Module (MCM): 15Y820 version 1.13.051

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.004

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.015

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.05.008

- Temperature Control Module (TCM): 15M871 version 1.08.002

- Mix Head Power Pack (FCM3): 16A039 version 1.10.003

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM, MCM and DGM Software:

- Re-wrote the DGM logic to use the same interface points as the new HFR CGM map (P/N: 19C801, documented in 19C810). This provides the user 2 additional diagnostic run screens to the left of the home screen, which graphically show the data being exchanged between the DGM and the HFR or NVH. Furthermore, it eliminates some problems with the old DGM operation.

- Modified the “Enable Operator Mode Cavitation Alarm” checkbox control on the Advanced #3 screen to read and operate as “Stop Dispense with Cavitation Error”. Hence the user has the capability to either stop or not stop a dispense if cavitation errors are enabled and the condition is detected, regardless of the dispense mode (Operator, shot or Sequence).

- Fixed some Air Nucleation issues when using that feature of the integrated Voltex Dynamic mixer option.

- Re-wrote the logic which numbered the higher Advanced setup screens.

Software Upgrade Token 16H821 Series ZBS

- System 16H822zbs version 1.13.024

- Advanced Display (ADM): 16E122 version 1.18.070

- Motor Control Module (MCM): 15Y820 version 1.13.041

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.004

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.015

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.009

- Temperature Control Module (TCM): 15M871 version 1.08.002

- Mix Head Power Pack (FCM3): 16A039 version 1.10.003

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM and USB Software:

- Added capability to turn On or OFF the Cavitation error generation logic via the ADM or the new CGM interface. An On or Off event will be generated when a transition occurs, or when powered up if the Cavitation generation logic is turned Off (events appear on event screen, and USB logs). The cavitation logic will remain active within the MCM regardless since it is used by the cold startup logic.

Software Upgrade Token 16H821 Series ZBR

- System 16H822zbr Version 1.13.019

- Advanced Display (ADM): 16E122 version 1.18.067

- Motor Control Module (MCM): 15Y820 version 1.13.040

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.003

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.015

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.009

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.10.003

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM and Mix Head Power Pack (FCM3):

- Modified L-Head operation to operate new L-Head rod position sensors.

- Fixed a Flashing Green/ Red Dispense Key display issue on the ADM home screen, when in Sequence Mode.

Software Upgrade Token 16H821 Series ZBP

- System 16H822zbp Version 1.13.018

- Advanced Display (ADM): 16E122 version 1.18.059

- Motor Control Module (MCM): 15Y820 version 1.13.036

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.003

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.015

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.009

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.024

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

- ADM, MCM and DGM Modules:

- Fixed an issue on the DGM that falsely reported a flow rate or dispense pressure change as rejected.

- Fixed an issue on the DGM where it would not report the correct analog voltage for the material pressure.

- Addressed an issue where the machine would process a red key, but not be able to start back up without a power cycle.

- Addressed an issue where the ADM would not refresh the run screen buttons properly when the machine was turned off and back on again.

- Improved logic within the ADM to better ensure the MCM and ADM have the same dispense modes after a boot up condition.

Software Upgrade Token 16H821 Series ZBN.

- System 16H822 Version 1.13.015

- Advanced Display (ADM): 16E122 version 1.18.045

- Motor Control Module (MCM): 15Y820 version 1.13.028

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.003

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.012

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.006

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.024

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM, MCM and Tank Stand Modules:

- Added the "Report Red (or Blue) High Lev. in bit 2" feature and check entries to the ADM Supply setup screen, to allow a user to report a high level condition (material at top sensor) in bit 2 of the tank level information provided on the field bus CGM interface.

- Added logic to prevent a user from selecting Weight mode and volumetric flow, and visa versa, since this situation at times creates an intermittent symptom of leaving the DV open after a shot or sequence mode dispense. Furthermore, the feature added un-necessary confusion and complexity, and no value.

- Added logic to better initialize system when a user presses the Power key, from an un-powered state.

- Fixed issue where the MCM would intermittently not report a ready state (when it should be ready) after the MCM would perform a non-circulation stall to pressure type dispense.

- Corrected issue where the MCM would intermittently not report the correct dispense amount (to ADM and PLC interface) after and sometimes during a non-circulation stall to pressure type dispense.

Software Upgrade Token 16H821 Series ZBM.

- System 16H822 Version 1.13.012

- Advanced Display (ADM): 16E122 version 1.18.045

- Motor Control Module (MCM): 15Y820 version 1.13.028

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.003

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.012

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.006

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.024

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM & MCM Modules:

- Added logic to lockout the power on/off key, when system in ADM Lockout mode (new CGM map feature). Also, added logic to update the lockout status better if the user is on a non-home run screen.

- Added logic to put the reversing valve in the center position if the Hot Middle PCB generates an over speed, over current, etc... error condition to help protect the reversing valve from burning up its coils in the event the spool is mechanically blocked for some reason. Logic was added also to recover from this situation at the start of a dispense, pump movement, stall to pressure sequence, etc. from an idle state.

- Added logic to improve reliability for ADM derived Ready signal sent to the CGM interface, plus improved logic to output a dispense # to the tank stands which is used for its leak detection logic.

Software Upgrade Token 16H821 Series ZBM.

- System 16H822 Version 1.13.010

- Advanced Display (ADM): 16E122 version 1.18.040

- Motor Control Module (MCM): 15Y820 version 1.13.027

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.003

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.012

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.006

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.024

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM & MCM Modules:

- Fixed an issue where the user could not properly change the flow set point on the Shot setup screens and the Home run screens (Shot & Operator modes) if the HFR/ NVH has the Custom Pump Size blue token inserted into the ADM module.

- Added an ‘Indications’ and ‘Commands’ Fieldbus Integration run screen to the left of the main home screen, available if a CGM module is Online, and the new HFR CGM map is being used (Map ID = 33). The new ‘Indications’ screen informs the user the critical data being reported to the controlling Robot or PLC. Likewise, the new ‘Commands’ screen informs the user the commands being requested by the controlling robot or PLC.

- Changed the default setting for the ‘Enable Operator Mode Cavitation Alarm’ & ‘Temperature Alarm Disables Dispense’ features to OFF, changed the default for the Inlet pressure for the Z-pumps (System #1 setup screen) from 200 PSI (13.x Bar) to 5.5 Bar, and changed the default ‘Post-Dispense Circulation’ time (NVH function) from 5 to 0 seconds (NO time limit).

- Fixed an issue when the user requests a dispense (via the ADM or foot switch) with the ‘Auto Circulate Between Dispenses’ feature ON, the pumps are idle, and the recirculation valves are closed. If the request occurs now, the HFR will start circulating material rather than trying to execute a dispense. This will make the system ‘Ready’ for the next dispense request.

Software Upgrade Token 16H821 Series ZBL.

- System 16H821 Version 1.13.07

- Advanced Display (ADM): 16E122 version 1.18.035

- Motor Control Module (MCM): 15Y820 version 1.13.022

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.003

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.003 (New Item Added)

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.012

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.006

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.024

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM, USB & Mix head Power Pack Modules:

- Added a "Accumulator Charges too Frequently” advisory, to warn user that a possible leak in the power pack hydraulic line, or the power pack accumulator needs adjustment.

- Added a “Power Pack Pressure Sensor Fault” alarm, if detected will shut-down the system.

- Added logic to shut down system if the Mix head generates an alarm level condition.

- Improved Mix head power pack communication interface to not require excessive bandwidth on the CAN network.

Software Upgrade Token 16H821 Series ZBL.

- System 16H821 Version 1.13.005

- Advanced Display (ADM): 16E122 version 1.18.032

- Motor Control Module (MCM): 15Y820 version 1.13.022

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.11.002

- Dynamic Mixer (Voltex) Module (FCM3): 18C787 version 1.03.003 (New Item Added)

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.012

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.013

- Discrete Gateway Module (DGM): 16D773 version 1.04.006

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.013

- Communications Gateway Module (CGM): 17P796 version 3.01.004

Change History

ADM, MCM, USB, Tank Stand & Voltex Dynamic Mixer Modules:

- Added capability for a HFR to operate with the new Voltex Dynamic Mixer. To support the new feature, a new "Mixer” run screen and a System #4 Setup screen was added to configure and control its integrated operation. If the HFR detects the presence of a Voltex FCM3, the screens will become available, and the user will be limited to flow control.

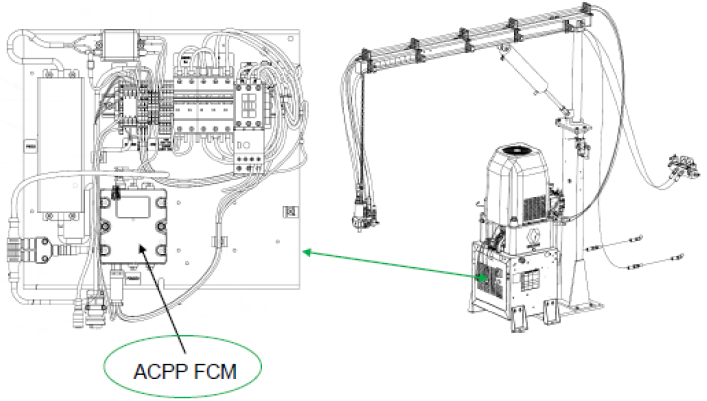

- To further support the new Voltex option, logic was added to support a new CGM /PLC interface. The new interface is more reliable, provides more data for the user, has a smaller map size, provides configurable registers where the user can assign the data to be monitored or controlled, and provides capability for the PLC to request a dispense over the field bus. The new interface will also support all HFR and NVH configurations. The new interface is available by ordering Graco 19C802 Token assembly. A sample PLC program along with support files and documentation is available on a USB stick by ordering Graco P/N 19C885.

- Improvements were incorporated to the data provided on the old CGM / PLC interface (P/N: 16J526), such as improvements to the Ready, DV Open/ Dispense active, dispensed amount and Tank level indications.

- The Leak Detection feature logic was re-written, and the feature was made available for all HFR type systems (Not just NVH). If a Tank Stand module is detected, the corresponding Red or Blue “Tank Leak Detect ON” option will become available on the Advanced #4 screen. If more than 2 automatic fill operations occur without the HFR (or NVH) performing a dispense, a Tank Leak Detect deviation will be generated and the system will shut down, if the feature is active.

- Hid the Advanced #8 screen, and added a “Use ADM to Program Token” option on the Advance #4 to make it visible. To provide the HFR or NVH system version to the user, a line was added on the Advanced #5 setup software component screen.

- Fixed an issue where an Invalid Set Point error would be generated if a PLC requests a new constant pressure control set point, and the recirculation valves are commanded open.

- Added logic to prohibit the use of constant Pressure control when the “Auto Circulate Between Dispenses” feature is turned ON.

- Corrected the main home run screen indication pertaining to the graphic illustrating the HFR or NVH is dispensing material out of the Dispense valve.

Ratio/ Inlet Pressure Monitoring Module (FCM3):

- Fixed an issue where the last flow meter calibration date was not being stored and displayed on the Calibration setup screen.

Discreet Gateway module (DGM3):

- The logic was updated to the GCA2 platform, and the data map locations were fixed to make it work with the new software.

Software Upgrade Token 16H821 Series ZBK.

- System 16H821 Version 1.12.014

- Advanced Display (ADM): 16E122 version 1.17.093

- Motor Control Module (MCM): 15Y820 version 1.12.069

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.10.009

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.013

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module (CGM): 17P796 version 3.01.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.002

- Ratio /Inlet Pressure Monitoring (FCM3): 16D755 version 1.01.012

Change History

o ADM Module:

- Added an Advanced #8 screen to provide the capability to program a token and the HFR using the ADM and an USB stick (16 Gigabytes or less). The additional screen also provides the user the capability to view the system version of the software.

o MCM and Ratio/ Inlet Pressure Monitoring Modules:

- Removed some diagnostic logic from the MCM module.

- Added the Ratio /Inlet Pressure Monitoring module to the main 16H821 programming token. Updated the module to the GCA2 platform for enhanced its performance.

- Fixed issue where the resettable & total material counters were being incremented excessively when a dispense was triggered by the expiration of the gel timer and the pumps were actively auto-circulating when triggered.

Software Upgrade Token 16H821 Series ZBJ.

- System 16H821 Version 1.12.013

- Advanced Display (ADM): 16E122 version 1.17.089

- Motor Control Module (MCM): 15Y820 version 1.12.068

- MCM Hot PCB Logic: 16C014 version 1.09.012

- USB Configuration (in ADM): 16G102 version 1.10.009

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.013

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module (CGM): 17P796 version 3.01.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.002

Change History

o ADM and MCM Modules:

- Added control logic & user entries to support a new "Pressurize Before Opening DV" feature when the "Auto Circulate Between Dispenses" feature is ON. The “Pressurize Before Opening DV” feature is NOT available if dispensing in constant pressure mode.

- Fixed a Gel timer issue when in Operator Mode & Auto circulate between dispenses.

- Created a Maximum Pressure option of 300 PSI (approximately 20.7 bar), when the MCM rotary switch is placed to position #5.

- Fixed an ADM to MCM communication issue of shot recipe data, if the user is operating in constant pressure mode.

- Re-wrote the logic which generates the “N4A1-D: Blue Pump Failed to Move”, to help prevent the generation of the condition when it does not occur.

o MCM Hot PCB Logic (NOTE- Token MUST be installed into MCM for this update to occur!):

- Re-wrote the encoder logic to help prevent the false generation of the “WBH1-A: Blue Motor Encoder Fault” error.

- Improved the communication and diagnostics between the 2 processors of the MCM module.

Software Upgrade Token 16H821 Series ZBJ.

- System 16H822 Version 1.12.007

- Advanced Display (ADM): 16E122 version 1.17.085

- Motor Control Module (MCM): 15Y820 version 1.12.052

- USB Configuration (in ADM): 16G102 version 1.10.009

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.013

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module (CGM): 17P796 version 3.01.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.002

Change History

- ADM, USB and MCM Modules:

- Added logic to the Gel Timer function to allow it to properly operate with the new “Auto Circulate Between Dispenses” function. Fixed some other foot switch and invalid recipe issues found pertaining to the Gel Timer function.

- Added a “Disable Setpoint Not Reached Errors” check box option on the Advanced #3 page to allow the user to disable the error generation logic.

- Improved CGM/ PLC interface for Mode selection (output byte 2), Dispense Amount Reported by HFR/NVH (input bytes 38-41), Dispense Status bit (input byte 0, bit 1), & Dispense Valve Open/Closed bit (input byte 0, bit 2).

- Fixed an issue with the reporting of the "Dispense System Ready to Dispense" bit (input byte 83, bit 5) on the CGM Interface.

- Added a "Dispense Valve Open, Dispense Active" bit (input byte 83, bit 7) on the CGM interface to replace the existing bits (byte 0 bits 1-2) for new designs.

- Added logic to the “Auto Circulate Between Dispenses” function to allow the user to start or stop the circulation process by setting or clearing the “System Startup bit” on the CGM Interface (Output byte 0, bit 7).

- Modified the “Change Flow Rate or Pressure Set Point” on the CGM interface (output bytes 12 – 15) to only allow the user to modify the dispense set point, and NOT the circulation set point. If the circulation flow rate set point needs to be altered, the user will need to change it on the HFR ADM module.

- Modified the “Flow Rate (or pressure if in constant pressure mode) Set point” reported on the CGM interface (input bytes 14 – 17) to only report the dispense set point and NOT the circulation set point.

- Added logic to the “Auto Circulate Between Dispenses” function to allow the user to start a dispense from an idle pump, preventing an issue where the user could not cancel a dispense from the foot switch.

- Improved the control and feedback of the CGM interface pertaining to the flow or pressure set points.

- Changed the text strings for both “WDF1” error conditions from “M1 Material Extend Fault” to “Dispense Valve Open Failure” and “Dispense Valve Failed to Close” to better describe the deviation and alarm conditions respectively.

o Mix Head Power Pack & Tank Stand Monitor/Control Modules:

- Rebuilt with new component libraries. No changes to operation added.

Software Upgrade Token 16H821 Series ZBH.

- System 16H822 Version 1.12.003

- Advanced Display (ADM): 16E122 version 1.17.057

- Motor Control Module (MCM): 15Y820 version 1.12.031

- USB Configuration (in ADM): 16G102 version 1.10.008

- Temperature Control Module (TCM): 15M871 version 1.07.005

- Mix Head Power Pack (FCM3): 16A039 version 1.09.012

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module (CGM): 17P796 version 3.01.004

- Tank Stand Monitor/Control (FCM3): 16A206 version 1.05.001

Change History

- ADM, USB, MCM and Mix Heat Power Pack Modules:

- Expanded the number of sequences to be stored and used by the HFR/ NVH system from 5 (“A” thru “E”) to 26 (“A” thru “Z”). Sequence position counters are not supported for sequences F thru Z. The new sequence mode sequences can by operated by the ADM or by a PLC using the CGM interface.

- Corrected a problem where the text for the time on the error and event screens was intermittently corrupted.

- To help minimize the occurrence of over temperature conditions for the High Power Inline Heater zones, logic was added to the ADM to detect the combination of an Inline Heater with a small pump (less than 20 CC’s). If the described combination was found, the ADM will now only turn ON the heater when there is flow detected thru the heat zone. Also, if the combination exists, the power output of the heater is limited to 1800 watts to help minimize the over shoot condition. Furthermore, logic was added which will automatically turn ON a zone if turned OFF (due to an over-temp. condition) once the material temperature is less than the set temperature & flow is detected thru the heater. The automatic turn ON logic is present for any Inline heater installed, the system can automatically recirculation material.

- The ADM logic was modified to allow the user to enter High and Low temperature alarm limits for a zone to within + or – 3 Co, rather than the previous limit of + or - 5 Co.

- To prevent an intermittent issue where a shot recipe element would get corrupted and contain an excessively large value, the ADM EE2 memory retrieval and storage logic was replaced with access logic to a new RAM buffer large enough to support all 100 shot recipe locations.

- Logic was added during the power up state to get the shot recipe data from EE2 to populate the new RAM buffer. If during the EE2 read process, a data element was found to be excessive for a shot number, the EE2 read process was repeated. If after 3 EE2 reads, the same result occurred, a new "WMCX-V: Questionable Shot Recipe Detected" advisory would be presented to the user. The same described EE2 read process is repeated if the user changes dispense modes (Pressure verses constant flow, weight verses time, etc…).

- Logic was added to CGM interface which generates a record level event if the user alters a shot number recipe element (rate or dispense amount). The new event; "ECGX-R: Dispense Recipe Altered by PLC" is recorded and can be viewed on the Event screen, and on the USB logs which also indicates the shot number which was altered.

- A new or better “System Ready” bit wide signal was created on the CGM interface. The new signal informs a controlling PLC if the HFR/ NVH system is “Ready” for a dispense request.

- Added the capability of CGM interface to set the over and under temperature alarm limits for the 2 high Power Inline Heater zones.

- Updated the Mix Heat Power Pack to the GCA2 software platform, to enable the product to have improved inner communication & other future upgrades.

Software Upgrade Token 16H821 Series ZBG.

- System 16H822 Version 1.12.001

- Advanced Display: 16E122 version 1.17.040

- Motor Control Module: 15Y820 version 1.12.030

- USB Configuration: 16G102 version 1.10.007

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module: 17P796 version 3.01.004

Change History

- ADM & MCM Modules:

- Updated the ADM to the GCA2 software platform, to enable the product to have improved inner communication & other future upgrades.

- Added a “Minimum Stall to Pressure %” feature, to enable the user to set the pressure set point after a stall to pressure dispense.

- Added the “Light Tower Option” user selection and logic, to support a custom light tower feature.

- Modified the “Maximum DV Response” feature, to allow the user to enter 0 milli-seconds to shorten the Dispense valve response time.

- Modified the “Maximum Recirculation Pressure” deviation generation logic to NOT be active ~ 2.5 after a dispense to recirculation transition, and ~ 2.5 seconds after the start of recirculation operation from a pump idle condition.

- Declassified all Heat Zone No/ low current alarms and chiller low temp alarms from alarms to deviations, so the zone does NOT turn OFF if condition occurs.

- Added significant logic to support the use of an Inlet pump pressure and Ratio monitoring system, which is currently not ready for release.

Software Upgrade Token 16H821 Series ZBF.

- Advanced Display: 16E122 version 1.16.032

- Motor Control Module: 15Y820 version 1.12.017

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module: 17P796 version 3.01.004

Change History

- ADM Modules:

- Fixed the intermittent false “CUCN - Field Bus Heartbeat Failure” error generation problem with the CGM interface. Re-wrote the logic completely to accept any dynamic signal received from the controlling logic (PLC), regardless if synched or not with the HFR generated Heat beat signal to the PLC. Signal generated from PLC simply needs to change state every 10-15 seconds, or faster.

- MCM Module:

- Enabled generation of pump cavitation errors if performing an auto recirculation operation, and the “Auto Circulate Between Dispenses” feature is turned ON.

- Fixed 2 intermittent footswitch interface issues, when an HFR is in Operator mode and the Auto-Circulation between dispenses feature is turned ON.

Software Upgrade Token 16H821 Series ZBE.

- Advanced Display: 16E122 version 1.16.022

- Motor Control Module: 15Y820 version 1.12.012

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module: 17P796 version 3.01.004

Change History

- ADM & MCM Module:

- Improved Sequence Mode operation and reliability when operated via the CGM (PLC) or ADM interfaces.

- Expanded Sequence Mode capability to work when operating a HFR with the “Auto Circulate Between Dispenses” feature turned ON.

- MCM Module:

- Fixed an “Auto Pressurize After Recirculation” feature issue which would not work in shot mode after the circulation valves were commanded closed prior to a dispense after the system material was circulating.

- Modified the stall to pressure logic to NOT reverse the pump at a dispense end, if the selected dispense amount (shot mode) is less than ~ 4 lengths of the pump. If longer, or in operator mode, the pump will reverse if past the mid-stroke position unconditionally.

Software Upgrade Token 16H821 Series ZBD.

- Advanced Display: 16E122 version 1.16.005

- Motor Control Module: 15Y820 version 1.12.001

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module: 17P796 version 3.01.004

Change History

ADM Module:

- Fixed Red/Blue tank heat zone offline issue when both an Inline and Tank heat zone exists for the same side and the system is NOT a NVH system.

Software Upgrade Token: 16H821 Series ZBC.

- Advanced Display: 16E122 version 1.16.001

- Motor Control Module: 15Y820 version 1.12.001

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.030

- Communications Gateway Module: 17P796 version 3.01.004

Change History

ADM and MCM Modules:

- Added the capability to circulate material when in shot mode, when the “HFR Recirculation Valves Installed” option is turned ON! Feature will NOT work if the P2/Fusion valve option is selected.

- Modified the “Auto Circulate Between Dispenses” feature to NOT momentarily stop the pumps during the dispense/ circulation transitions. Furthermore, the feature now works when in Shot mode, hence the system will function similar to a NVH type system without the need for an AC power pack.

DGM Modules:

- Modified logic to allow the DGM to alter the state of the circulation valves when in shot mode, and the “HFR Recirculation Valves Installed” option is turned ON.

- Fixed an issue where the system would initialize with an active error, even if no system errors were present.

CGM Module:

- Changed software part number to an improved version of the same logic.

Software Upgrade Token: 16H821 Series ZBB

- Advanced Display: 16E122 version 1.15.111

- Motor Control Module: 15Y820 version 1.11.112

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.029

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM and MCM Modules:

- Added an “Auto Circulate Between Dispenses” feature, which if the user activates (via a check box option on the Advanced #6 screen), will automatically recirculate material thru the recirculating valves when NOT dispensing. The “HFR Recirculation Valves Installed” option must be set to turn ON the new feature.

- The “Ready Lamp” logic was modified to provide a NOT Ready signal to the user, if the system is recirculating, with the “Auto Circulate Between Dispenses” feature turned OFF.

- Fixed an issue were the Run Screen Ratio displayed from the Ratio Monitoring system was inverted when the Red Pump size was larger than the Blue Pump.

- To make the “Auto Circulate Between Dispenses” feature work, the logic will no longer disable dispense requests at the end of a Semi-Automatic recirculation dispense if the feature is active (“Post Dispense Shot Disable” feature).

DGM Modules:

- Logic which reports the error number to the interface was re-written to reflect the current errors present in the HFR system. The existing logic was severely dated, and did not include reporting current conditions.

Software Upgrade Token: 16H821 Series ZBA.

- Advanced Display: 16E122 version 1.15.105

- Motor Control Module: 15Y820 version 1.11.103

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.026

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM and MCM Modules:

- Improved the pump “Cavitation Detection” logic to better detect when the smaller pumps (65 cc and lower) are starved with material at the pump inlet. Furthermore, the logic improvements will better detect when the outbound pump pressure is less than the “Inlet” pressure entered on the “System #1” setup screen. In the HFR systems, the Red and Blue “Pump Cavitation” deviations (codes “DDA1” and DDB2”) can be configured as an “Alarm” where it will terminate a dispense if generated. The condition is an “Alarm” in shot and sequence modes by default, and also in Operator mode if the “Enable Operator Mode Cavitation Alarm” feature is checked on the “Advanced #3 screen.

- Added a “Factory Test Mode” feature which is activated with a press and hold ADM key sequence shortly after boot up. If activated, the pump movement will be simulated in software to verify the operation of the pump reversing switches during a factory mode test. The feature is intended to assist with the testing of a MCM module, and not intended for normal operation.

Software Upgrade Token 16H821 Series ZAZ.

- Advanced Display: 16E122 version 1.15.092

- Motor Control Module: 15Y820 version 1.11.095

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.026

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM and MCM Modules:

- Added logic to drive a “Ready Lamp”, typically installed on a dispense valve. The logic is turned ON when the user selects the new “Control Dispense Ready Light” check box control, on the new Advanced #7 setup screen.

- Fixed an issue when the user is controlling an HFR via a CGM module and the system is in sequence mode.

- Added a “Blue Token Reader” feature, to the Advanced #7 screen. To use, insert programmed Blue token, press the soft-key, and the ADM will read the data on the token and display a file part number and description on the screen.

Software Upgrade Token 16H821 Series ZAY.

- Advanced Display: 16E122 version 1.15.079

- Motor Control Module: 15Y820 version 1.11.094

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.026

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM and MCM Modules:

- Modified logic to allow “Post Dispense Shot Disable” durations for up to 30 seconds, from the previous maximum of 5 seconds. This feature is available on the System #2 setup screen.

- Modified logic to store the On/ Off state of the “2x Trigger For Dispense” and “Dispense From Home Position” features on the MCM module, to prevent an intermittent communication problem from not implementing the feature if turned ON.

- Fixed issue if the customer is using a Ratio Monitoring accessory (P/N: 24J318) where the actual dispense ratio displayed on the ADM was inverted.

- Added logic to drive a “Ready Lamp”, which is currently NOT part of the standard software package.

Software Upgrade Token 16H821 Series ZAW.

- Advanced Display: 16E122 version 1.15.073

- Motor Control Module: 15Y820 version 1.11.083

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.026

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM and MCM Modules:

- Added a “Higher Pressure” pump option to the “Controlling/ Stall Pump” selection on the Advanced #6 setup screen. When selected, the logic will control pressure (constant pressure mode) and stall (constant flow or pressure modes) to the pump which has the higher of the two pressures. The difference between the pump pressures has to exceed a minimum amount (over 2.4 Bar) before the controlling pump is changed.

- Fixed an issue where the HFR was not reporting the correct actual flow when dispensing in constant pressure mode.

- Modified the logic to be more forgiving when the controlling logic (PLC or equivalent) changes the shot number selection (shot mode) when using the communication gateway (CGM) control interface.

Software Upgrade Token 16H821 Series ZAV.

- Advanced Display: 16E122 version 1.15.070

- Motor Control Module: 15Y820 version 1.11.075

- USB Configuration: 16G102 version 1.09.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.011

- Discrete Gateway Module (DGM): 16D773 version 1.03.026

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM, MCM, USB, DGM & Pwr. Pack Modules:

- Added a significant amount of logic to support the new “Small Dispense Kit”, P/N: U82702. The kit enables the HFR product to dispense consistently much smaller amounts than previously available or allowed by the product.

- Added a “Disable Pressure Imbalance Alarms” check box option, to make setting up the machine easier, especially for static mixer applications.

- Eliminated a significant amount of the MCM interface (to save RAM space), which forced the rebuild of the DGM and Mix Head Power Pack projects. Consequently, if this software is used to update an existing system, the software in all the modules will need to be updated accordingly. It will NOT be compatible with older software versions.

Software Upgrade Token 16H821 Series ZAU.

- Advanced Display: 16E122 version 1.15.053

- Motor Control Module: 15Y820 version 1.11.050

- USB Configuration: 16G102 version 1.09.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.010

- Discrete Gateway Module: 16D773 version 1.03.025

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM, MCM & USB Modules:

- Added capability for the user to select the “Controlling/ Stall Pump” in the event the application needs to control (pressure mode) or stall (flow and pressure modes) to the opposite pump the automatic selection logic uses (bigger pump, or blue pump if sizes are the same). The new selection option was added to the Advanced #6 setup screen.

- Added “Maximum DV Response” numeric entry control to enable users to select the maximum response time (in milli-seconds) for opening or closing the dispense valve at the start and end of a dispense. This feature is very useful if dispensing very short dispenses, and/or for bead type dispensing. Entries from 10 to 330 milli-seconds are allowed. The entry was added to the Advanced #6 setup screen.

- Fixed a stall to pressure issue which occurs when dispensing very short dispenses which are terminated before the pumps get to the requested flow (or pressure if in pressure mode). The product will now better support very short, or rapid fire type dispense applications.

- Added the “Monitor” and “Manual Fill” option selections to the Supply Setup screen when the user has selected the 3 level sensor type tank for the corresponding material.

- Added 2 columns to the USB logs to support the addition of 2 possible auxiliary heat zones, which is currently available in a custom version of the HFR logic.

Software Upgrade Token 16H821 Series ZAT.

- Advanced Display: 16E122 version 1.15.032

- Motor Control Module: 15Y820 version 1.11.042

- USB Configuration: 16G102 version 1.08.005

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.010

- Discrete Gateway Module: 16D773 version 1.03.025

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM, MCM & Mix Head Power Modules:

- Added Night Mode capability for Semi-Automatic Recirculation systems which have “HFR Recirculation Valves Installed”. Night Mode gives the user capability to periodically or schedule a pump turn On (with the heat ON) or off future event to condition the materials prior to dispense.

- Added Accumulator Charge Cycle counters to be accessed via the ADM setup maintenance screen. This feature only applies to full recirculation configuration HFR’s. Added logging of these new counters, along with the DV and Pump cycle counters to the “SETTINGS.TXT” file when user performs a USB download.

- Added “Tap to High Pressure Recirculation” feature to the full recirculation configuration HFR’s, to enable the user to put system into High Pressure Recirculation using the footswitch, without dispensing material.

- Fixed issue when user changes between Recirculation and Dispense modes states on the main operator mode run screen using a DGM interface, and the set point gets corrupted.

Software Upgrade Token 16H821 Series ZAS.

- Advanced Display: 16E122 version 1.15.020

- Motor Control Module: 15Y820 version 1.11.034

- USB Configuration: 16G102 version 1.08.005

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.025

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM, MCM & USB Modules:

- Added a “Micro Motion” feature and selectable option (in an Advanced setup screen) to enable the HFR to allow slow flow rate selections down to an equivalent rate of 0.16 cycles/ minute from the standard 3 cycles/ minute.

- Added data stored to the “SETTINGS.TXT” USB down load file which will document the micro Motion selection, along with other system parameters stored in the MCM module.

Software Upgrade Token: 16H821 Series ZAR.

- Advanced Display: 16E122 version 1.15.018

- Motor Control Module: 15Y820 version 1.11.029

- USB Configuration: 16G102 version 1.08.004

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.025

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM and ADM USB Modules:

- Added a "Heater(s) are OFF" advisory, warning users of the condition for critical applications when the "Temperature Alarm Disables Dispense" feature is active.

- Re-spaced the Error and Event run screen columns to better fit and to ease reading of the screen information.

Software Upgrade Token: 16H821 Series ZAP.

- Advanced Display: 16E122 version 1.15.016

- Motor Control Module: 15Y820 version 1.11.029

- USB Configuration: 16G102 version 1.08.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.025

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM, MCM, & DGM Modules:

- Added Different Set Point storage for Dispense and Manual/ Semi-Automatic Recirculation rates

- Fixed some Recirculation <--> Flow Dispense transition issues.

- Made the "Disable Dispensing from Display" feature not prohibit a recirculation dispense and work correctly with a Park Operation.

- Improved and increased the stall to pressure logic and its rate, and Fixed the "Limit Rate on Stall to Pressure" feature when transitioning out a recirculation dispense and pressurizing the lines prior to the next dispense.

Software Upgrade Token: 16H821 Series ZAN.

- Advanced Display: 16E122 version 1.15.013

- Motor Control Module: 15Y820 version 1.11.021

- USB Configuration: 16G102 version 1.08.003

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.024

- Communications Gateway Module: 15U193 version 2.06.004

Change History

ADM, MCM, USB and DGM Modules:

- Added Manual + Semi-Automatic Recirculation Functions.

- 70 cc pump selection.

- Base purge capability.

- Other Misc. Items.

Software Upgrade Token: 16H821 Series ZAM.

- Advanced Display: 16E122 version 1.14.030

- Motor Control Module: 15Y820 version 1.10.187

- USB Configuration: 16G102 version 1.08.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.023

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Fixed Go button issue with a recirculation system Learn Mode (LM) Dispense.

- Loosened acceptable LM dispense extreme pump position typical values on main setup CAL screen. (16E122).

Software Upgrade Token: 16H821 Series ZAL.

- Advanced Display: 16E122 version 1.14.029

- Motor Control Module: 15Y820 version 1.10.187

- USB Configuration: 16G102 version 1.08.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.023

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Added Custom Pump Capability to logic (16E122 & 16D773).

- Enhanced GCM interface when controlling device alters recipe or shot number requests.

- Fixed a Set Point request issue with the DGM3.

- MCM logic (15Y820) was rebuilt to incorporate updated files.

- No added logic or fixes were incorporated into the change.

Software Upgrade Token: 16H821 Series ZAK.

- Advanced Display: 16E122 version 1.14.018

- Motor Control Module: 15Y820 version 1.10.185

- USB Configuration: 16G102 version 1.08.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.020

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Added logic more logic to MCM (15Y820) to fix a highly intermittent issue reported at a distributor location, where the HFR would get stuck implementing a set point change during an active dispense, and would ignore additional set point requests via the CGM interface.

Software Upgrade Token: 16H821 Series ZAJ.

- Advanced Display: 16E122 version 1.14.018

- Motor Control Module: 15Y820 version 1.10.184

- USB Configuration: 16G102 version 1.08.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.08.001

- Discrete Gateway Module: 16D773 version 1.03.020

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Added logic to MCM (15Y820) to enable operation with a NIP Sensor input to the footswitch, which routinely oscillates between on and off states at a rapid rate. Also added logic to the P2/Fusion DV state machine to help prevent a Set Point Not reached deviation condition.

- Added logic to ADM (16E122) to make Set Point requests via the CGM interface work more reliable.

- Added logic to Mix Head Power Pack (16A039) to check for a valve stuck in the charge position for 60 seconds, indicating that the system is not reaching pressure.

Software Upgrade Token: 16H821 Series ZAH.

- Advanced Display: 16E122 version 1.14.015

- Motor Control Module: 15Y820 version 1.10.177

- USB Configuration: 16G102 version 1.08.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.07.001

- Discrete Gateway Module: 16D773 version 1.03.020

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Added a Pre Dispense Delay Feature, selectable for user (0 ((default)) – 60 seconds), to address a Nip Sensor Application at a customer location (16E122 & 15Y820).

Software Upgrade Token: 16H821 Series ZAG.

- Advanced Display: 16E122 version 1.14.014

- Motor Control Module: 15Y820 version 1.10.174

- USB Configuration: 16G102 version 1.08.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.07.001

- Discrete Gateway Module: 16D773 version 1.03.020

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Fixed issue with the DGM interface (16E122).

- Added some diagnostic capabilities to the DGM software (16D773).

Software Upgrade Token: 16H821 Series ZAF.

- Advanced Display: 16E122 version 1.14.013

- Motor Control Module: 15Y820 version 1.10.174

- USB Configuration: 16G102 version 1.08.002

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.07.001

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Improvements were made to Modules 15Y820, 16E122, 16G102, and 16A039

- The logic was improved for the Motor Control Module and Advanced Display to address a potential memory loss issue.

- The logic for clearing a pump cavitation deviation was improved.

- The logic concerning screen reset was improved in the Advanced Display when the system is in Communications Gateway Module control.

- The logic for reporting error logs in the USB Configuration was improved.

- A field in the run diagnostic screen for displaying real time Mix Head Hydraulic pressure was added to the Advanced Display.

- The logic to clear a Mix Head Power Pack over pressure condition was improved.

Software Upgrade Token: 16H821 Series ZAE.

- Advanced Display: 16E122 version 1.14.009

- Motor Control Module: 15Y820 version 1.10.169

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.06.003

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Changes were made to Modules 15Y820 and 16E122.

- Screen navigation was improved in 16E122, to prevent a screen from “Hanging” when transitioning between screens.

- The flow control logic in 15Y820 was improved to make it better and more quickly adapt to when the restriction for the pumps changes.

Software Upgrade Token: 16H821 Series ZAD.

- Advanced Display: 16E122 version 1.14.002

- Motor Control Module: 15Y820 version 1.10.159

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.06.003

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Changes were made to Modules 15Y820, 16E122 and 16A039.

- Error code was added to warn user of condition when No pressure is built in AC Power pack after startup (16A039).

- A Post Dispense, Shot Request Prohibit feature (from 0 to 5 seconds) was added (16E122 & 15Y820). Entry was added to System #2 Setup screen on ADM. Default will be 0 seconds.

- An initial stall to pressure situation for a manually controlled DV configuration was corrected (15Y820).

Software Upgrade Token: 16H821 Series ZAC.

- Advanced Display: 16E122 version 1.14.001

- Motor Control Module: 15Y820 version 1.10.157

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.06.001

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Changes were made to Modules 15Y820 & 16E122.

- Included Gram Calibration table for NVH Foams.

- Weight Based Dispense for Systems that use AC Power Pack.

- Ratio Assurance support for Systems that use AC Power Pack.

- Leak Detection added; 2 refills without dispensing triggers a “leak”.

- System will only refill in a mode that supports dispensing.

- Pre-Poly Refresh support for NVH Foams.

Software Upgrade Token: 16H821 Series ZAB.

- Advanced Display: 16E122 version 1.13.064

- Motor Control Module: 15Y820 version 1.10.150

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.004

Change History

- Changes were made to Modules 15U193.

- Changes were made to fix issues with PCF product.

- Change does not affect HFR CGM.

Software Upgrade Token: 16H821 Series Z.

- Advanced Display: 16E122 version 1.13.064

- Motor Control Module: 15Y820 version 1.10.150

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.003

Change History

- Changes were made to Modules 15Y820 & 16E122.

- Added pump sizes 90, 140 and 150 to the pump selections.

- Added logic to better represent the start and end of a dispense for the CGM interface.

- Added logic to enhance operation at start of a Dispense for applications where the HFR does NOT control the dispense valve.

Software Upgrade Token: 16H821 Series Y.

- Advanced Display: 16E122 version 1.13.061

- Motor Control Module: 15Y820 version 1.10.118

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.003 Advanced Display: 16E122 version 1.13.061

- Motor Control Module: 15Y820 version 1.10.118

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.003

Change History

16E122 & 15U193

- Corrected logic at CGM interface to allow user to control pressure set points, and flow set points in units of measure which are not g/s or cc/s.

Software Upgrade Token: 16H821 Series W.

- Advanced Display: 16E122 version 1.13.058

- Motor Control Module: 15Y820 version 1.10.118

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.002

Change History

15U193

- Updated CGM 15U193 to fix an issue with ProfiNet modules where a rename of the station from the ADM would cause the module to reset and not recover; fixed an issue with EEPROM longevity.

Software Upgrade Token: 16H821 Series V.

- Advanced Display: 16E122 version 1.13.058

- Motor Control Module: 15Y820 version 1.10.118

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.001

Change History

16E122 & 15Y820

- The reliability of the Heartbeat signal on CGM interface was improved.

- An intermittent 500 PSI set point change issue was fixed.

- Additional interlock logic to prevent logic from requesting too much current when stalling to pressure was added.

Software Upgrade Token: 16H821 Series U.

- Advanced Display: 16E122 version 1.13.053

- Motor Control Module: 15Y820 version 1.10.117

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.001

Change History

16E122 & 15Y820

- Added an additional Dispense Valve Open/Close indication to the Communications Gateway Module map. Added a stall to pressure rate limiter option, which is selectable via the Advanced Setup screen on the Advanced Display Module (default is OFF). Also added some logic to improve how the shot event logging on the USB logs works.

Software Upgrade Token: 16H821 Series T.

- Advanced Display: 16E122 version 1.13.052

- Motor Control Module: 15Y820 version 1.10.115

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.015

- Communications Gateway Module: 15U193 version 2.06.001

Change History

16E122

- Added 35 and 45 CC Pump sizes. Fixed field reported issue with controlling DV via the CGM.

15Y820

- Fixed issue to assist production (does not affect user operation).

16D773

- Added logic to support the Recirculation type HFR Configuration.

Software Upgrade Token: 16H821 Series Q.

- Advanced Display: 16E122 version 1.13.050

- Motor Control Module: 15Y820 version 1.10.102

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.081

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.06.001

Change History

16E122, 15Y820

- Changed reporting of current flow to CGM/Controlling computer to 0 when pumps are idle.

16A039

- Raised High pressure threshold to 2600 from 2500 PSI

Software Upgrade Token: 16H821 Series P.

- Advanced Display: 16E122 version 1.13.048

- Motor Control Module: 15Y820 version 1.10.096

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.080

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.06.001

Change History

16E122

- Added 105 CC Pump option. Reclassified all the No Heat Rise errors from Alarms to Deviations, to prevent a corresponding zone from turning OFF when a particular zone is unable to reach an excessive high set temperature. Added a predispense state indication by making the dispense key yellow, and making the soft-key visible when machine is controlled by an external device.

16A039

- Added additional noise immunity logic when charging the accumulator.

15Y820

- Added additional diagnostic capabilities, which do not effect normal operation.

Software Upgrade Token: 16H821 Series N.

- Advanced Display: 16E122 version 1.13.047

- Motor Control Module: 15Y820 version 1.10.087

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.078

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.06.001

Change History

16E122

- Corrected Dispense Amount reported to the CGM and USB Logs.

Software Upgrade Token: 16H821 Series M.

- Advanced Display: 16E122 version 1.13.046

- Motor Control Module: 15Y820 version 1.10.087

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.078

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.06.001

Change History

16E122

- Enhancements were added to assist in the manufacturing process. No functional changes were made.

Software Upgrade Token: 16H821 Series L.

- Advanced Display: 16E122 version 1.13.032

- Motor Control Module: 15Y820 version 1.10.087

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.078

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.06.001

Change History

15Y820

- For circulation systems, logic was added to increase the shot size repeatability for low ratio applications (3:1 to 1:1).

16E122

- A 75 cc Pump option was added to the Setup System 1 screen, to support the new pump size.

Software Upgrade Token: 16H821 Series K.

- Advanced Display: 16E122 version 1.13.031

- Motor Control Module: 15Y820 version 1.10.085

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.078

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.06.001

Change History

15Y820

- For circulation systems in night mode, if the pumps are moving and the Turn pumps off button is pressed or the night mode timer expires, the pumps will park.

16E122

- Added shot offset time column to all modes except Pressure and Time shot recipes. I moved SG entry fields to System Screen 3. I removed weight mode calibration. Fixed EE PROM initialization values for Periodic Night Mode and Pre-Dispense circulation time. Removed Variable Ratio Demo Mode functionality For circulation systems in night mode, if the pumps are moving and the Turn pumps off button is pressed or the night mode timer expires, the pumps will park. Added option to disable dispense with low supply alarm.

16A039

- Added logic to enable operation with other GMS based products (VRM, VPM and future products).

15U193

- We updated component code to speed up internal network data transmissions.

Software Upgrade Token: 16H821 Series H.

- Advanced Display: 16E122 version 1.12.004

- Motor Control Module: 15Y820 version 1.10.077

- USB Configuration: 16G102 version 1.08.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.072

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.04.002

Change History

15Y820

- Added automatic gain control logic to improve performance for high pressure or low pump velocity, constant flow applications. This shortened the response time significantly to a pressure for flow rate change request.

16E122, 16G102

- Fixed issues with the USB logs. I removed un-used screens or controls for certain HFR configurations.

16A039

- Added logic to enable operation with other GMS based products (VRM, VPM and future products).

Software Upgrade Token: 16H821 Series H.

- Advanced Display: 16E122 version 1.11.002

- Motor Control Module: 15Y820 version 1.10.070

- USB Configuration: 16G102 version 1.07.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.071

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.04.002

Change History

16E122, 15Y820

- Added 1-Sided Look Ahead & Home position Feature for the start of Recirculation. System Dispense. Fixed issue w/ P2/Fusion Gun configuration. Enforced a Pre-Dispense state if user changes flow rate while in High Pressure recirculation mode. I also added translations for some of the ADM strings.

16A039

- Added a feature to assist with recirculation during machine production testing. This does not affect end user operation.

Software Upgrade Token: 16H821 Series G.

- Advanced Display: 16E122 version 1.10.002

- Motor Control Module: 15Y820 version 1.10.015

- USB Configuration: 16G102 version 1.07.001

- Temperature Control Module: 15M871 version 1.07.005

- Mix Head Power Pack: 16A039 version 1.05.069

- Discrete Gateway Module: 16D773 version 1.03.002

- Communications Gateway Module: 15U193 version 2.04.002

Change History

16E122

- Added logic for ADM NVH Blue Token feature. I fixed an issue (RTD2) with the monitor zones.

15Y820

- Added additional checks for the Prox. Switch for a Straight head recirculation application.

16D773

- Added some logic to support a Discreet Gateway and P2/Fusion Gun HFR configuration.

15M871

- Issues addressed pertaining to features used by the Diesel reactor project. This change does not affect this product at all.

16G102

- Added strings to support additional events added to the USB files saved.

Software Upgrade Token: 16H821 Series E.

- Advanced Display: 16E122 version 1.08.001

- Motor Control Module: 15Y820 version 1.10.002

- USB Configuration: 16G102 version 1.05.002

- Temperature Control Module: 15M871 version 1.06.001

- Mix Head Power Pack: 16A039 version 1.05.069

- Discrete Gateway Module: 16D773 version 1.02.001

- Communications Gateway Module: 15U193 version 2.04.002

Change History

16E122

- Added support for cold start-up; minimum shot time is 0.25 seconds.

15Y820

- Added support for minimum shot time of 0.25 seconds; dispense valve on hydraulic power pack is now controlled from MCM for any straight head; cold start-up for circulation systems; improved cavitation detection.

Software Upgrade Token: 16H821 Series D.

Software Upgrade Token: 16H821 Series D.

- Advanced Display: 16E122 version 1.07.254

- Motor Control Module: 15Y820 version 1.09.001

- USB Configuration: 16G102 version 1.05.002

- Temperature Control Module: 15M871 version 1.06.001

- Mix Head Power Pack: 16A039 version 1.05.069

- Discrete Gateway Module: 16D773 version 1.02.001

- Communications Gateway Module: 15U193 version 2.04.002

Change History

16E122

- Support for 65/86cc pumps.

15Y820

- Support for 65/86cc pumps; improved accuracy of material counters.

16A039

- Dispense control is now from MCM for any straight head.

Software Upgrade Token: 16H821 Series C.

- Advanced Display: 16E122 version 1.07.001

- Motor Control Module: 15Y820 version 1.08.001

- USB Configuration: 16G102 version 1.05.002

- Temperature Control Module: 15M871 version 1.06.001

- Mix Head Power Pack: 16A039 version 1.04.001

- Discrete Gateway Module: 16D773 version 1.02.001

- Communications Gateway Module: 15U193 version 2.04.002

Change History

16E122

- Added Temperature Monitoring Zones 15Y820.

Software Upgrade Token: 16H821 Series B.

- Advanced Display: 16E122 version 1.06.001

- Motor Control Module: 15Y820 version 1.07.004

- USB Configuration: 16G102 version 1.05.002

- Temperature Control Module: 15M871 version 1.06.001

- Mix Head Power Pack: 16A039 version 1.04.001

- Discrete Gateway Module: 16D773 version 1.02.001

- Communications Gateway Module: 15U193 version 2.04.002

Change History

- Added CGM 15U193 support.

- 15M871 update for above temperature alarm error.

- 15Y820 updated flow meter support.

- 16E122 Added ratio selection (RED:BLUE or BLUE:RED).

Software Upgrade Token: 16H821 Series A.

- Advanced Display: 16E122 version 1.05.001

- Motor Control Module: 15Y820 version 1.03.001

- USB Configuration: 16G102 version 1.05.002

- Temperature Control Module: 15M871 version 1.05.006

- Mix Head Power Pack: 16A039 version 1.03.001

- Discrete Gateway Module: 16D773 version 1.02.001

Change History

- Initial Release.

Software Upgrade Token: 16D942 Series L.

- Advanced Display: 15X468 version 1.04.001

- Motor Control Module: 15Y820 version 1.10.077

- USB Configuration: 16D461 version 1.03.001

- Temperature Control Module: 15M871 version 1.07.005

- Discrete Gateway Module: 16D773 version 1.03.002

- Mix Head Power Pack 16A039 version 1.05.072

Change History

15Y820

- Updated to Latest Configuration, with Higher CPK (for Recirc. Systems only), I instant SP change and Automatic Control Gain capabilities.

16A039

- Logic added to support other non-standard HFR configurations. These changes do not affect this product.

Software Upgrade Token: 16D942 Series K.

- Advanced Display: 15X468 version 1.04.001

- Motor Control Module: 15Y820 version 1.10.015

- USB Configuration: 16D461 version 1.03.001

- Temperature Control Module: 15M871 version 1.07.005

- Discrete Gateway Module: 16D773 version 1.03.002

- Mix Head Power Pack 16A039 version 1.05.069

Change History

15Y820

- Updated to Latest Configuration to support NVH type Options, including Cold start, and double footswitch trigger.

15M871

- Changes made which do not effect this product.

Software Upgrade Token: 16D942 Series J.

- Advanced Display: 15X468 version 1.04.001

- Motor Control Module: 15Y820 version 1.07.004

- USB Configuration: 16D461 version 1.03.001

- Temperature Control Module: 15M871 version 1.06.001

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.04.001

Change History

15M871

- Update for error in above temperature alarm.

16A039

- Added support for Prime Mode.

Software Upgrade Token: 16D942 Series J.

- Advanced Display: 15X468 version 1.04.001

- Motor Control Module: 15Y820 version 1.06.001

- USB Configuration: 16D461 version 1.03.001

- Temperature Control Module: 15M871 version 1.05.006

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.03.001

Change History

- Support for new ADM (24E451).

Software Upgrade Token: 16D942 Series H.

- Advanced Display: 15X468 version 1.03.001

- Motor Control Module: 15Y820 version 1.04.001

- USB Configuration: 16D461 version 1.03.001

- Temperature Control Module: 15M871 version 1.05.006

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.03.001

Change History

- Flow meter support added.

Software Upgrade Token: 16D942 Series G.

- Advanced Display: 15X468 version 1.03.001

- Motor Control Module: 15Y820 version 1.03.001

- USB Configuration: 16D461 version 1.03.001

- Temperature Control Module: 15M871 version 1.05.006

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.03.001

Change History

- Allow sprays between 3000 and 3500 without over pressuring Control based on larger pump in pressure mode; previous was to control to B-side regardless of pump ratio.

Software Upgrade Token: 16D942 Series F.

- Advanced Display: 15X468 version 1.02.001

- Motor Control Module: 15Y820 version 1.02.001

- USB Configuration: 16D461 version 1.02.001

- Temperature Control Module: 15M871 version 1.05.006

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.02.001

Change History

- Added Discrete Gateway Module to token.

Software Upgrade Token: 16D942 Series D.

- Advanced Display: 15X468 version 1.01.029

- Motor Control Module: 15Y820 version 1.01.011

- USB Configuration: 16D461 version 1.02.001

- Temperature Control Module: 15M871 version 1.05.006

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.01.004

Change History

- Corrected Material/Weight Counters.

- Corrected Cycle Counters not resetting until after a dispense.

- Fixed pump parking in recirculation mode Added 5 second delay to Mix Head Power pack from turning AC motor on to charging accumulator.

Software Upgrade Token: 16D942 Series C.

- Advanced Display: 15X468 version 1.01.027

- Motor Control Module: 15Y820 version 1.01.007

- USB Configuration: 16D461 version 1.02.001

- Temperature Control Module: 15M871 version 1.05.006

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.01.004

Change History

- Corrected issue with pump failed to move error.

Software Upgrade Token: 16D942 Series B.

- Advanced Display: 15X468 version 1.01.024

- Motor Control Module: 15Y820 version 1.01.001

- USB Configuration: 16D461 version 1.02.001

- Temperature Control Module: 15M871 version 1.05.006

- Discrete Gateway Module: 16D773 version 1.02.001

- Mix Head Power Pack 16A039 version 1.01.001

Change History

- Corrected outstanding issues from initial release.

Software Upgrade Token: 16D942 Series A.

- Advanced Display: 15X468 version 1.01.001

- Motor Control Module: 15Y820 version 1.01.001

- USB Configuration: 16D461 version 1.01.001

- Temperature Control Module: 15M871 version 1.05.006

Change History

- Initial Release.

Software Upgrade Token: 16G407 Series B.

- Ratio Monitoring: 16D755 version 1.01.002

Change History

- Initial Release.

Software Upgrade Token: 16G584 Series G.

- Tank Stand *(Red or Blue): 16A206 version 1.04.002

- Temperature Control Module: 15M871 version 1.07.005

Change History