ProMix PD2K Dual Panel Software Change History

ProMix® PD2K Dual Panel Electronic Proportioner Software

for ProMix® PD2K Dual Panel Models MC0502, MC1002, MC2002, MC3002, MC4002, AC0502, AC1002, AC2002

This software version is ONLY applicable for the models explicitly mentioned above. Do not try to update other Graco electronic proportioners using this software.

Software Upgrade Token: 17N631 Series F

- Advanced Display: 17L357 version 2.01.008

- Fluid Plate: 17L356 version 1.03.003

- USB Configuration: 17L355 version 2.01.001

- Color Change: 16N914 version 1.01.004

- Booth Control: 16N913 version 2.00.001

- Modbus CGM: 16V799 version 1.02.001

- Added Custom Valve Mapping feature for color change modules.

- Added air/solvent chop capability for flushing out pumps.

- Added alarm and troubleshooting information screens to ADM.

- Added 1K mode optimization for color change and material dispensing as well as system configuration and set up screens on the ADM.

- Added Mix-at-Belt circulation system – safe mode feature that will block circulation path in the case of an alarm to prevent a user from dispensing material that bypasses the pump.

- Inlet pressure alarms are now disabled while pump power is off.

- Disabled solvent flow alarms while user is working in Maintenance screens on ADM.

- Volume calibration screen will not immediately clear when pump is returned to Standby. This will allow user to see dispensed volume before exiting the screen.

- Systems with color change will default to using Flush sequence assigned to Recipe 0, rather than Flush sequence 1, when performing first color change after system power has been turned on.

Software Upgrade Token: 17N631 Series D

- Advanced Display: 17L357 version 1.02.007

- Fluid Plate: 17L356 version 1.02.004

- USB Configuration: 17L355 version 1.02.003

- Color Change: 16N914 version 1.01.004

- Booth Control: 16N913 version 2.00.001

- Modbus CGM: 16V799 version 1.02.001

- Added PROFINET communications which requires two CGM modules. A new PD2K Dual Panel PROFINET installation kit (part number 25D997) is available with all necessary hardware.

The following individual software modules are updated as part of this release.

- Advanced Display: 17L357 version 1.02.003

- USB Configuration: 17L355 version 1.02.001

- Fluid Plate: 17L356 version 1.02.003

This version of software is compatible for upgrade with any previous version for the applicable ProMix® PD2K Dual Panel models listed at the top of this document.

While some of the screens of the display module may change, depending on the version of software installed prior to performing the upgrade, none of the usage or event records will be deleted or altered.

*Important Note* This update will reset all of the stored data in the Flush and Recipe memory space. It is important that the Flush and Recipe data be recorded prior to upgrading software, then it will have to be manually re-entered after completing the software update.

It is good practice to do a USB download prior to installing the new software. This will create a backup of programmed settings as well as a record of recent usage and event logs. See Operation Manual 3A4186 or 3A4486 for details on USB Downloads.

For systems with mix-at-wall manifolds, the air/solvent chop feature is now available for a more aggressive and efficient approach to purging material from the gun.

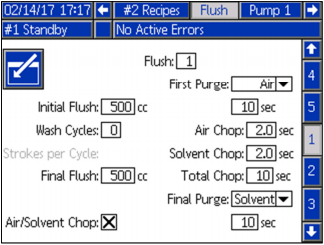

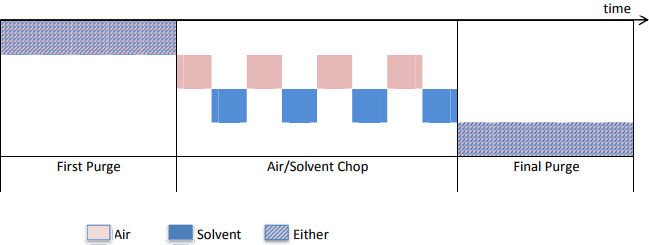

Air/Solvent Chop replaces the standard Gun Purge Time parameter on the Flush screen. Instead the purge is split into 3-phases: First Purge, Chop, and Final Purge. The Chop Phase will always start with Air. Only the color flush sequence may use air chop, if a flush sequence that has air/solvent chop enabled is selected for a catalyst, that recipe will be invalidated.

First Purge:

- Material Selection – The user may select the material for the first purge phase to be either Air or Solvent.

- Time – The length of the first purge phase, dispensing only the material selected.

Chop:

- Air Chop Duty Cycle – The length of each pulse of air.

- Solvent Chop Duty Cycle – The length of each pulse of solvent.

- Total Chop Time – The total length of the air and solvent chop. (Does not have to be an even multiple of the chop duty cycles.)

Final Purge:

- Material Selection – The user may select the material for the final purge phase to be either Air or Solvent.

- Time – The length of the final purge phase, dispensing only the material selected.

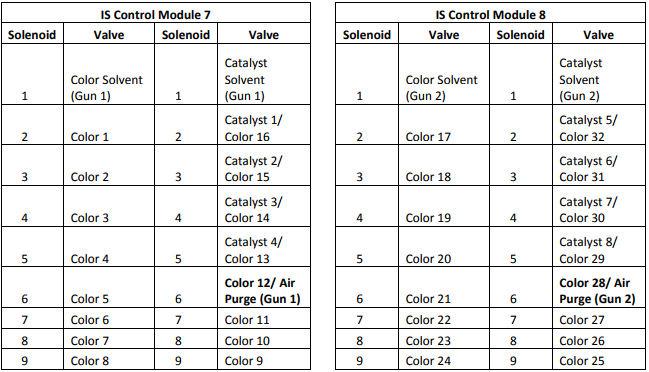

The Air Purge valve will replace color 12 on Mix Unit #1 and color 28 on Mix Unit #2. The system will automatically adjust color assignments if there is a conflict as these colors may not be used if air purge is required. For more information on hardware kits for the air purge valve and installation instructions, see Installation manual 332457 or 332458.

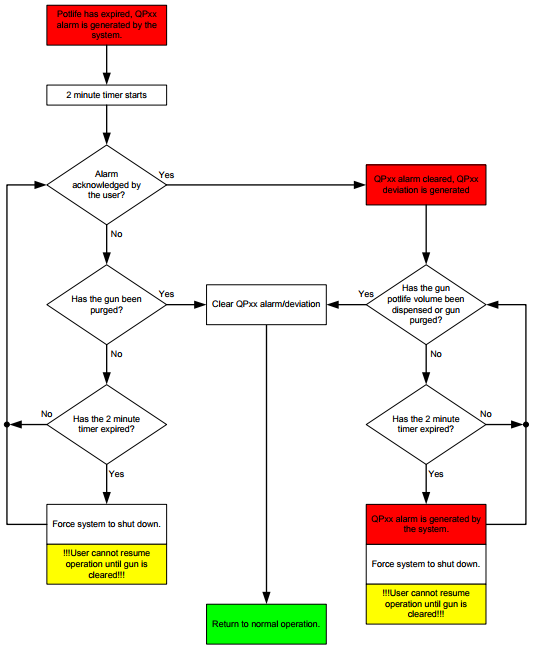

Once a potlife expiration alarm has been generated, the user has two minutes to clear the expired material from the gun. If after two minutes the material has not been cleared, the system will shut down and operation may not be restored until the gun has been purged. This process is illustrated in the flow chart below.

A user entered timer set point will automatically park the Mix Unit’s pumps to help prevent material from hardening on the pump rods. The timer will only run while gun(s) is(are) purged and the Mix Unit is in Standby mode. Each Mix Unit will run independent of the other. This setting is found on System Settings 4. The default value (0 min) disables this feature.

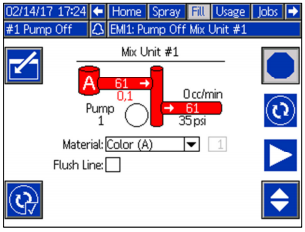

For pumps that have color change valves, but only one color or catalyst, and remain filled with material when the system is shut down, the user may use the Pre-Fill button to skip flushing after system power has been restored. The Pre-Fill button appears on the lower left of the Fill screen when applicable.

- When transitioning from Standby mode to Mix mode, the Exceeded Max Flow alarm and Differential Pressure alarms (“A over B” and “B over A”) will be suppressed for 10 seconds to allow the system to stabilize.

- For automatic systems that have Flow Control set to “Recipe”, the user may adjust the target set point from the Spray screen while mixing and the system will automatically adjust the stored value for future use.

- If pump outlet pressure is automatically relieved but continues to rise while the system is not in use, after 2 hours the system may try to automatically relieve pressure again.

- When using the air cutoff valve, the atomizing air will not be cut off in the event of an alarm until the user has acknowledged the alarm on the ADM or Booth Control module.

- When performing fast color change between filled guns, the potlife timer will no longer be reset.

- The Low Flow timer alarm threshold will now adjust to Target Flow Rate changes in Mix mode for automatic systems using Flow Control.

- Corrected a small offset in the pressure reading calculation.

- The Pump Status (PLC input) registers no longer shows status of Standby during short pauses in the flush and/or prime sequence.

- The system will no longer allow the gun to Mix Fill if the remote hoses were purged, but gun purge was not completed.

- Now preventing pumps involved in color change from attempting to automatically relieve pressure if the feature is enabled.

1. Turn off system power.

2. Remove the cover from the rear of the ADM with a 3/32 hex wrench.

3. For automatic systems, model ACxxxx, remove the blue key token and set to the side momentarily. Manual systems, model MCxxxx, will not have a blue key token.

4. Insert the black software token into the slot.

5. Turn system power back on.

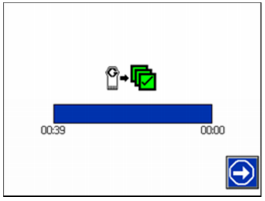

6. Once the system has booted up, the software will begin to load automatically and will be indicated by a progress bar.

7. A green check mark will indicate the software has completed loading successfully. Acknowledge the process has completed by pressing the arrow softkey.

8. It is now safe to turn off system power again.

9. Remove the black software token.

10. If you had a blue key token, re-install it at this time. Replace the ADM token cover.

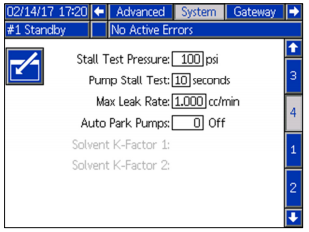

11. When system power is restored, the software versions can be verified on Setup Screen – Advanced Screen 4.

Read, understand and follow all instruction manuals and warning labels supplied with all equipment. Only trained and qualified personnel should perform repairs on the equipment. To access the latest manuals in your preferred language go to “www.Graco.com” and use the “Search” function.