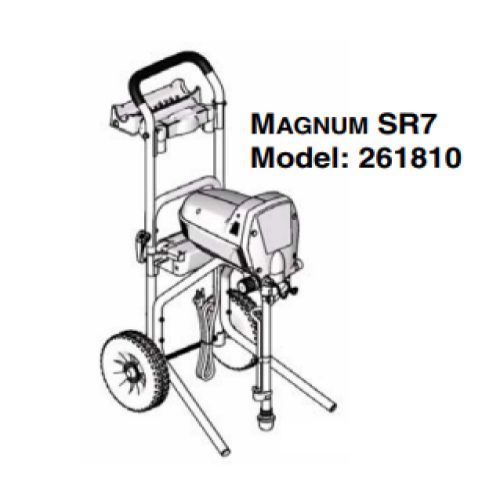

Magnum SR7 - 261810

Sprayer is Not Priming

Clearing a Tip Clog

Basic Trouble Shooting

Is the sprayer turning on?

Is it priming?

Does it spray at all?

There are several causes:

1. The needle is held open with debris.

2. The grey nut at the back of the gun is turned too tight, loosen it slightly.

3. The needle may be worn and needs to be replaced. Have the gun serviced or install a new repair kit for the specific gun you are using.

Is it a new sprayer?

Jog the motor.

Did this resolve the issue?

The issue is resolved.

Powerflush the sprayer.

Did this resolve the issue?

Have you already been spraying today?

Check the following:

- Turn up the pressure control knob.

- Plug directly into a non-GFCI outlet.

- Check for a burnt fuse (ProX models only).

Did this resolve the issue?

Reverse the spray tip and try to clear a tip clog.

Did this resolve the issue?

The issue is resolved.

Check the following:

- If you sprayed a lot today allow motor to cool for 30 minutes and try again.

- Verify extension cord is at least 14 gauge and no longer than 50 ft.

- Turn up the pressure control knob.

- Plug directly into a non-GFCI outlet.

- Check for a burnt fuse (ProX models only).

Did this resolve the issue?

Follow these steps:

- Make sure the suction tube (the larger, braided tube) and the strainer are completely submerged in the paint.

- Some paints are very thick and require the pump to slow down to prime. Turn the on/off switch ON and then OFF until the pump is about to stops and then turn the sprayer ON and then OFF again. You may need to do this a few times until paint works its way into the pump and out the drain tube (smaller clear tube).

- Remove the suction tube (larger, braided tube). Insert the pointed end of a pencil into the inlet and push up to free the inlet valve ball.

- Remove and clean the outlet valve. (See component identification and troubleshooting in your owner’s manual.)

- Remove and clean the inlet valve. (See component identification and troubleshooting in your owner’s manual.) Be sure not to lose the inlet ball (some models have a spring as well).

- Remove the strainer and connect the Power Flush adapter and a garden hose to the suction tube. Following the directions in your owner’s manual, flush the sprayer with water for one minute. Reinstall the strainer on the suction tube, submerge the suction tube in the paint and prime the sprayer.

Make sure the unit is plugged into a working outlet. If it is, turn the sprayer on and then turn the sprayer’s pressure control knob clockwise until the motor starts running.

When the gun trigger is released, the motor and pump will automatically turn off. Once you pull the gun trigger and start spraying, the motor and pump will turn on again. This is normal operation and eliminates constant motor noise and reduces wear for longer life.

If the motor continues to run when the gun trigger is released, it is not primed.

Make sure the Prime/Spray Valve is pointed forward in the Spray position

The spray tip is likely clogged. Turn the spray tip 180 degrees to the unclog position, aim the spray gun into a bucket and pull the trigger for one second to clear the clog. Turn the spray tip back to the spray position and resume spraying.

The best way to reduce tip clogs is to strain you paint of the larger debris.

Make sure the pressure control is turned up to a higher spray pressure. Try moving closer to the surface. If you continue to see lines in your pattern, you may need a larger tip size if you sprayer can support it (the largest tip that the Project Painter Plus and X5/LTS15 can support is the tip that is included). Otherwise, add a small amount of water or solvent, depending upon your material. Be sure to work the water or solvent into the paint that is in your paint hose by reversing the tip and spraying the paint back into the paint bucket until the thinner material is worked into the paint hose. Don’t forget to turn your spray tip back to the spray position.

You most likely have a tip plug. Turn the spray tip 180 degrees to the unclog position, aim the spray gun into a bucket and pull the trigger for one second to clear the clog. Turn the spray tip back to the spray position and resume spraying.

The pump needs to be serviced or replaced.

The spray hose connection is not tight. Use a wrench to tighten the spray hose to the sprayer and to the gun.

Turn AllControl clockwise to increase pressure setting.

• Try a different outlet or plug in a compatible working appliance to test outlet.

• Reset building circuit breaker or replace fuse.

Check for broken insulation or wires. Replace electric cord if damaged.

Take sprayer to Graco/MAGNUM authorized service center.

Replace extension cord. Read Grounding and Electric Requirements, page 5.

Unplug sprayer from outlet. If frozen do NOT try to start sprayer until it is completely thawed or you may damage the motor, control board and/or drivetrain. Make sure power switch is OFF. Place sprayer in a warm area for several hours. Then plug in power cord and turn sprayer ON. Slowly increase pressure setting to see if motor will start. If paint is hardened in sprayer, pump packings, valves, drivetrain or pressure switch may need to be replaced. Take sprayer to Graco/MAGNUM authorized service center.

Turn AllControl to OFF, pause 2-3 seconds and then turn AllControl to STORAGE to relieve pressure.

Turn Pressure Control Knob clockwise to increase pressure setting.

Turn Prime/Spray Valve to PRIME position (pointing down).

Clean debris off inlet strainer and make sure suction tube is immersed in paint.

Remove inlet housing. Clean or replace ball and seat.

Remove suction tube and place a pencil into the inlet section to dislodge the ball, allowing pump to prime properly. OR Power Flush sprayer (see Operation manual). AutoPrime may need replacement. For Project Painter 7: plug in unit and listen for “tap” in pump. SR7 and ProX7 and 9: turn power switch ON and listen for “tap” in pump. If you do not hear “tap”, AutoPrime is damaged. Take sprayer to Graco/MAGNUM authorized service center.

Tighten suction tube connection. Inspect for cracks or vacuum leaks.

Insert screw driver in slot and remove Easy-Access™ door, page 10, SR7 models or page 12, ProX7 and ProX9 models. Unscrew outlet valve with a 3/4 in. socket. Remove and clean assembly.

Make sure suction tube is immersed in paint.

Remove suction tube from paint. Prime pump with water or solvent-based flushing fluid.

Take sprayer to Graco/MAGNUM authorized service center.

Turn AllControl to PRIME/CLEAN PUMP position.

Clean debris off inlet strainer and make sure suction tube is immersed in paint.

Take sprayer to Graco/MAGNUM authorized service center.

Prime pump (see Operation manual).

Make sure suction tube is immersed in paint.

Refill hopper or paint pail. Reprime sprayer.

Project Painter 5 (hopper mode): Inlet tube fitting improperly or not securely attached to hopper elbow fitting. Project Painter 7, SR7, ProX 7 and 9: Tighten suction tube connection. Inspect for cracks or vacuum leaks. If cracked or damaged, replace suction tube.

Take sprayer to Graco/MAGNUM authorized service center.

Read Pump does not prime section in Troubleshooting, page 17.

Material is going on too thick.

Move gun faster.

Choose a spray tip with smaller hole size.

Choose spray tip with wider fan.

Make sure gun is far enough from surface.

Material is going on too thin.

Move gun slower.

Choose spray tip with larger hole size.

Choose spray tip with narrower fan.

Make sure gun is close enough to surface.

SR7, ProX7 and ProX9 - Pressure control switch is worn and causing excessive pressure variation.

Take sprayer to Graco/MAGNUM authorized service center.

Spray gun trigger lock is locked.

Rotate trigger safety lever to unlock trigger lock, page 14.

SR7, ProX7 and ProX9 - Pressure control switch is worn.

Take sprayer to Graco/MAGNUM authorized service center.

Sprayer is over pressurizing.

Take sprayer to Graco/MAGNUM authorized service center.

Pump packings are worn.

Replace pump packings.

Keep vent holes clear of obstructions and overspray and keep sprayer open to air.

Replace extension cord. Read Grounding and Electrical Requirements, page 5.

Use electrical generator with a proper voltage regulator.

Decrease pressure setting or increase tip size.

Clear spray tip clog. See page 19.

See troubleshooting section “Sprayer runs, but pump does not prime or looses prime while in use.” on page 32.

Project Painter 5 and Project Painter 7 Sprayers -Slowly turn AllControl to HI SPRAY to increase pressure setting

or

SR7, ProX 7 and ProX9 - Turn Pressure Control Knob clockwise to increase pressure setting which will turn on motor to build pressure.

Unclog spray tip (see Operation manual).

Clean or replace InstaClean fluid filter (see Operation manual).

Clean or replace gun fluid filter (see Operation manual).

Replace spray tip.

Rotate arrow-shaped handle on spray tip so it points forward in SPRAY position (see Operation manual).

Select smaller spray tip.

Replace spray tip.

Replace extension cord. Grounding and Electrical Requirements, page 5.

Clean or replace spray gun fluid filter (see Operation manual).

Clean or replace InstaClean fluid filter (see Operation manual).

Check for worn pump valves.

a. Prime sprayer with paint

b. Trigger gun momentarily. When trigger is released, pump should cycle momentarily and stop. If pump continues to cycle, pump valves may be worn.

Take sprayer to Graco/MAGNUM authorized service center.

Thin material.

Remove section of hose.

Remove suction tube from paint. Prime pump with water or flushing solvent-based flushing fluid.

Tighten suction tube connection. Inspect for cracks or vacuum leaks.

Clean/replace prime tube as necessary. Take sprayer to Graco/MAGNUM authorized service center if valve is plugged.

Unclog spray tip (see Operation manual).

Free up circuit (unplug things), or use a less busy circuit.

Check broken insulation or wires. Replace electrical cord if damaged.

• Plug in something that you know is working to test extension cord.

• Replace extension cord.

Dirty or dried paint

Clean handle parts.